- GST No. 03ADGPA7594Q1Z3

- Send SMS

- Send Email

| Business Type | Manufacturer, Supplier, Retailer |

| Type | Hydraulic Press |

| Application | Bending Plate, Bending Sheet |

| Certification | CE Certified |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Weight

100-1000kg

Color

Multi Colour

Voltage

1-3kw, 3-6kw

Automatic Grade

Automatic

Power

110V, 220V

Driven Type

Hydraulic

Warranty

1year

We are engaged in manufacturing, exporting and supplying Hydraulic Press Brake Machine in the market. With assured long functional life, our Hydraulic Press Brake Machine is widely accepted Press Brake Machine all over the world. Our Hydraulic Press Brake Machine is fabricated using optimum quality components in order to ensure flawless machine and high performance. Hydraulic Press Brake Machine is used for bending sheet and plate metal, most commonly sheet metal in the various industries.

Standard Accessories

- Main Drive Motor.

- Etectrical controI paneI with selection of 'AUTO', 'INCH' & 'SINGLE CYCLE AUTO' mode operations.

- Movable work station with pair of foot switch.

- Pair of lifting links.

- Pair of sheet support.

- Fine stroke adjustment rod with limit switch.

- Manual back gauge with micro setting.

- One suitabte five way die & Punch of EN-9*. . (unhardened and ungrounded)

- Centralized Iubrication system with flow controI valves for adequate Iubrication.

- Ram tilting arrangement on selected models.

Standard Accessortes (NC Control)

- Main Drive Motor.

- Selection of 'AUTO' & 'MANUAL' mode through screen"

- Two axis dedicated controtler with LCD monochrome screen & numeric keypad.

- 128 jobs X 16 bends program memory.

- Movable work station with pair of foot switch.

- AC Servo motor with resolver for back gauge drive.

- Hardened & Grounded Ball screw.

- Linear motion bearing on guide rods.

- Highty precise glass tube optical linear scate for accurate Y-axis position.

- Pair of lifting tinks.

- Pair of sheet support.

- One suitable five way die & Punch of EN-9.* (unhardened and ungrounded).

- Centralized lubrication system with flow controI valves for adequate Iubrication.

- Ram tilting arrangement on selected models

Optional Accessories

- AC servo drives for R-axis & Z-axis control of back gauging.

- Anti deflection unit (Manual / Motorized / Automatic)

- Sliding sheet support with Swing away stoppers.

- Hardened tools & special toots.**

- Hydraulic tool clamprng.

- Photo electric fingers safety guard.

- Higher throat depth.

- Automatic Iubrication system.

- Fast cycling models for high productivity.

- First fill of hydraulic oil.

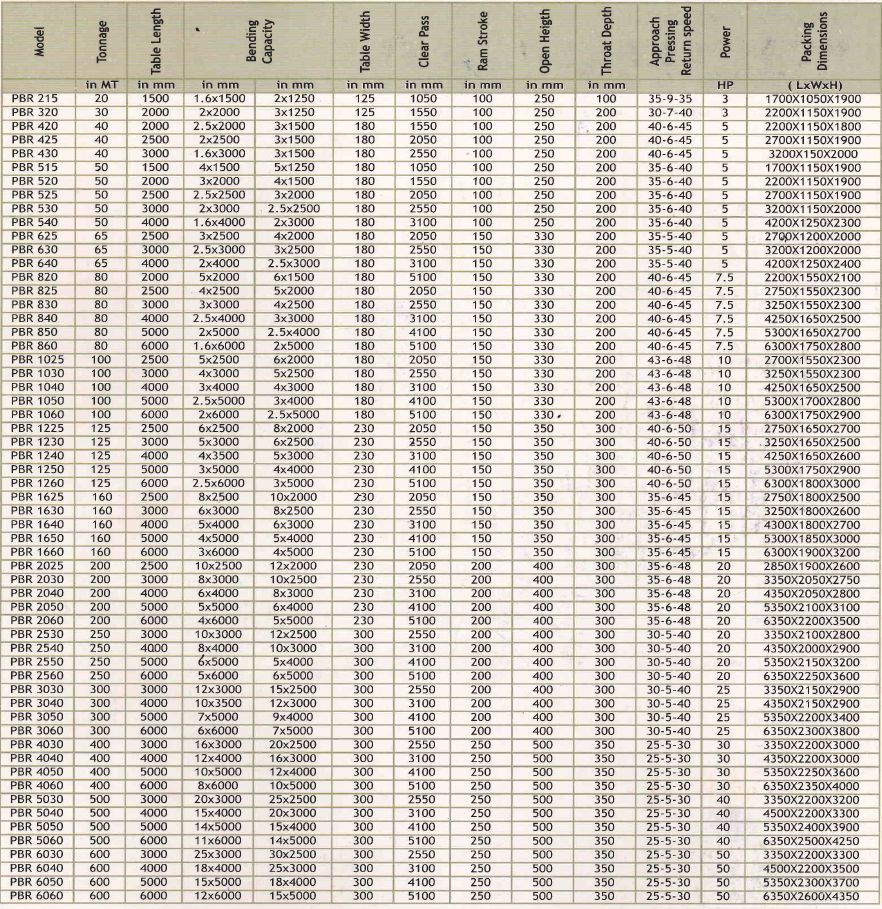

Technical Specifications

Looking for "Hydraulic Press Brake Machine" ?

Unit