- GST No. 03ADGPA7594Q1Z3

- Send SMS

- Send Email

| Business Type | Manufacturer, Supplier, Retailer |

| Type | Boring Machine |

| Certification | CE Certified |

| Application | Industrial |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

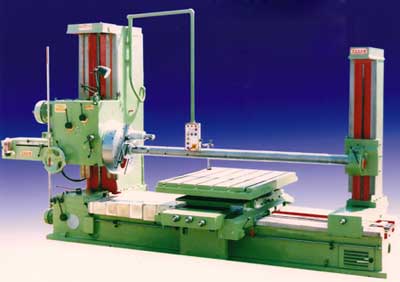

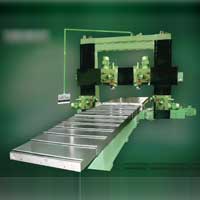

We are reckoned as one of the prominent High Precision Horizontal Boring Machine Manufacturers in India. The use of optimum quality materials in the manufacturing of the Horizontal Boring Machine ensures high durability, tensile strength and resistivity to adverse conditions. The unmatched quality and unsurpassable performance has attracted various national as well as international clients to place repeated orders for the Horizontal Boring Machines. Additionally, customers are eased with the availability of the Horizontal Boring Machines with latest configurations confirming to the international standards.

Salient Features :

- The Verniers Casting is done with the mixture of 25% Steel & Ferro Chrome etc. To acquire proper Brinell Hardness & it is also seasoned for at least six months. The machine is manufactured to Grade-1 Limits of accuracy.

- Heavily ribbed box type bed & sturdy box type columns to withstand the heavy cutting force even at Elevated Height.

- High Accuracy of machining due to accurately Ground * reliable Guide ways of bed & pillars etc. and fine positioning by Dial Gauges & Verniers Digital Readout System.

- Longitudinal & Cross Table Traverses, Vertical Travel of Head Stock & Boring Supports are provided with Rapid movements as well as feeds.

- Provision of inching spindle speeds and feeds of gearbox.

- All Gears are precision cut on imported Mother Machinery to ensure Smooth and Silent running.

- Precise Synchronized Vertical Travel of Head Stock & Boring Stay Support.

- The Machine is manufactured according to DR. SCHLESINGERS ACCEPTANCE TEST CHART.

- SPECIAL ARRANGEMENT : To set Rotary Table Perfectly at right angle.

- SAFETY CLUTCHES :

- Facing Mechanism

- Sliding Mechanism of Cross Slide

- Rotary Movement of Work Table

- Working Spindle Longitudinal Movement.

- Apart from above safety measures, suitable Shear Pins are also provided for the total safety of machine.

- Adjustable stoppers to trip longitudinal & vertical feeds at desire points are also provided.

- Hand operated knurled socket attached to head Stock Drive Motor & Operated wheel attached to feed gear Box.

- Motor for the safe engagement of speeds & feeds respectively.

- Mechanical clamping of all axes.

- Manual Boring head height setting adjustment-with a lever attached to Feed Gear Box.

- Conveniently arranged & simple Control Panel system ensures easy operations.

Technical Specifications

| MODEL NO | NHB80 | NHB100 | NHB110 | NHB125 | NHB130 | NHB 150 |

| Alloy Steel Work Spindle Hardened & Ground-Diameter | 80 | 100 | 110 | 125 | 130 | 150 |

| Morse Taper Number | 5 | 6 | 6 | 6 | 6 | 6 |

| Max. Longitudinal Movements of Working Spindle | 510 | 510 | 510 | 600 | 600 | 650 |

| Number of Spindle Speeds | 9 | 9 | 9 | 9 | 9 | 9 |

| Range of Spindle Speeds – R.P.M. | 15 to 300 | 15 to 250 | 15 to 250 | 15 to 250 | 15 to 250 | 12 to 250 |

| Longitudinal Work Spindle Feeds Nos. | 9 | 9 | 9 | 9 | 9 | 9 |

| Max. Height of the Spindle Axis from Table Surface | 925 | 1000 | 1100 | 1200 | 1300 | 1500 |

| Min. Height of the Spindle Axis from Table Surface | 25 | 30 | 30 | 30 | 30 | 30 |

| Dimensions of the Rotary Table | 900*1105 | 1030*1375 | 1100*1450 | 1220*1675 | 1320*1775 | 1500*2000 |

| Longitudinal table Traverse | 1625 | 1775 | 1925 | 2050 | 2800 | 2950 |

| Long. Table Traverse Feeds (Including one Rapid) | 10 | 10 | 10 | 10 | 10 | 10 |

| Transversal Table Travel Feeds (Including one Rapid) | 10 | 10 | 10 | 10 | 10 | 10 |

| Vertical Head Stock Travel Feeds (Including one Rapid) | 4 | 4 | 4 | 10 | 10 | 10 |

| Rotary Table Automatic Feeds (Including one Rapid) | 10 | 10 | 10 | 10 | 10 | 10 |

| Max. Cross Movement of the Table | 1000 | 1100 | 1300 | 1500 | 2000 | 2000 |

| Max. Distance between Stay Bearing & Facing Head | 2400 | 2690 | 2800 | 2950 | 3600 | 3950 |

| Facing Head Diameter | 505 | 555 | 600 | 650 | 650 | 700 |

| Weight Approx. in Kgs. | 8500 | 9500 | 11000 | 16000 | 17000 | 19000 |